Why the polyethylene tube from Elite Pipe?

The application of the new technology of co-extrusion in the manufacture of polyethylene pipes for Elite Pipe Company has many advantages, some of which we mention briefly.

🔘 Polyethylene pipes (three layers) HDPE pe100-RC

⚫️ Polyethylene pipes (full black) HDPE-PE100-RC

🔶 To all contractors, companies and state departments, they have large projects in the field of irrigation to deliver drinking water to residential homes, in all governorates of Iraq.

✅-For the first time and the only company in the Middle East producing polyethylene pipes - pe100 - HDPE -RC, two types

Three layers, one layer and conforms to German specifications with the best quality and competitive price.

✅- Raw raw materials 100% without adding any recycled materials.

✅With 50-year guarantees, provided that the quality control examination and laboratory examination (chemical, physical and field)

✅- The inner layer, white in color, is healthy and maintains the purity of pure drinking water. Algae growth and rotting water

✅ Endure high pressures and tolerate its underground installation

✅-The outer layer, resistant to uv sunlight

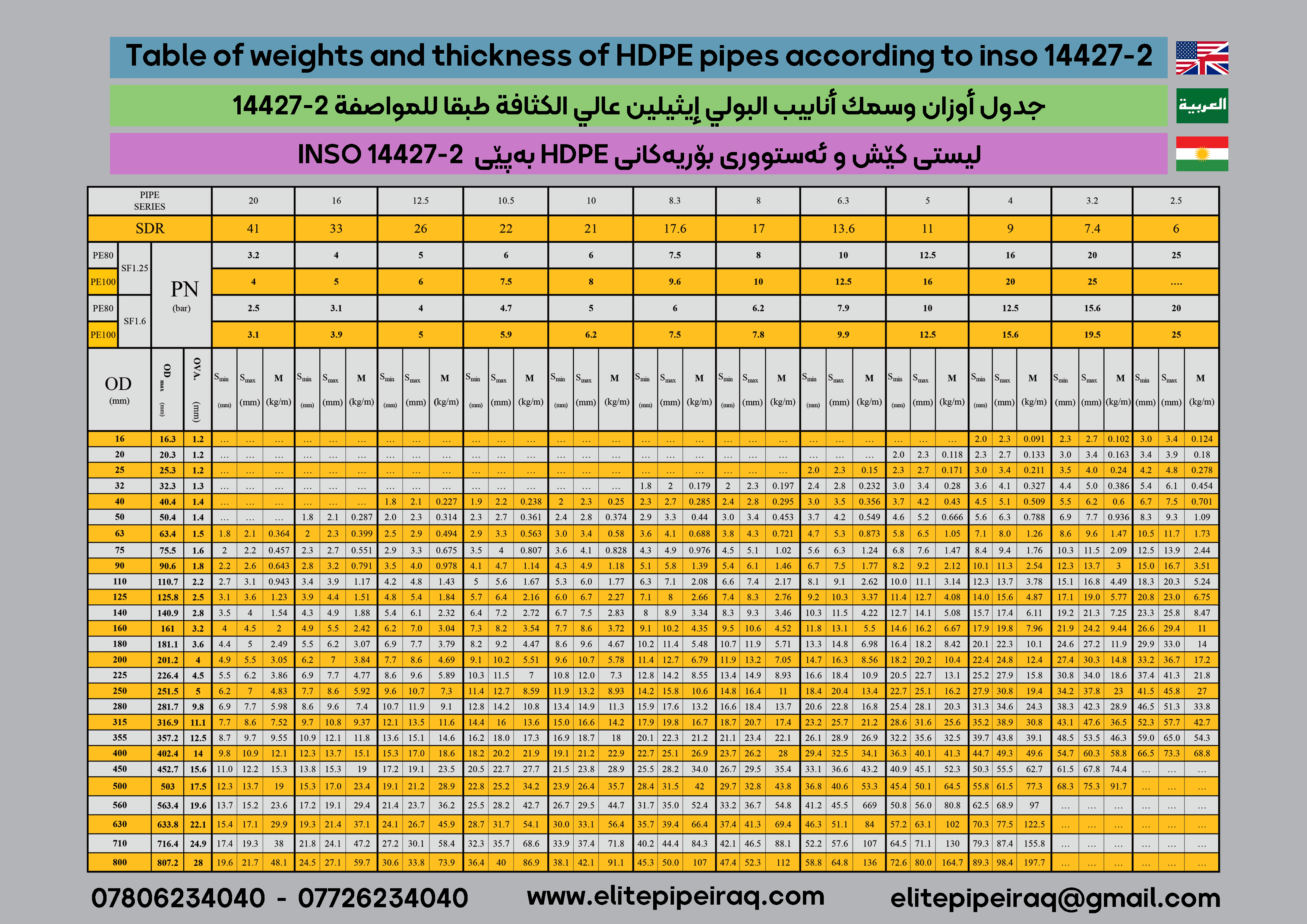

✅-We have sizes from 20 mm to 800 mm, up to 25 bars.

✅- Smooth and easily weldable, the duration of your work is limited,

✅ We have all the accessories for dividing, reversing and welding polyethylene and electrofusion 🔘

✅ We have all sizes of pipe ironing machine

✅ Confidence and credibility in providing the customer on time

✅-Please wholesale only, as for small and individual quantities, you can contact the WhatsApp page to direct you to our nearest agents from your workplace.

Comparison of single-layer and three-layer polyethylene pipes inside white

questions and answers

Frequently Asked Questions

Polyethylene (PE) HDPE PE100 is a high density polyethylene material classified as PE100, indicating its high performance properties and adherence to set quality standards. It is widely used in various applications due to its excellent properties.

HDPE PE100 polyethylene pipe offers many advantages, including:

- Exceptional durability and resistance to abrasion, chemicals and UV rays.

- High flexibility, allowing easy installation and adaptability to terrain changes.

- Lightweight structure, which makes it easy to handle and transport.

- Long service life, with a typical lifespan of up to 50 years.

- Good flow characteristics, ensuring efficient fluid transfer.

- Recyclability, making it an environmentally friendly choice.

HDPE PE100 polyethylene pipes find wide-ranging applications in various industries, including:

- Water supply and distribution networks for drinking and non-potable water.

- Irrigation systems for agricultural fields, gardens and landscaping.

- Gas distribution pipelines for residential, commercial and industrial uses.

- Mining operations to transport mud and tailings.

- Drainage systems to manage rainwater and wastewater.

- Industrial processes that require transportation of fluids and chemicals.

Yes, HDPE PE100 Polyethylene Pipe is well suited for underground installation. They have excellent resistance to soil movements, external pressures, and chemicals normally found in soil. Their flexibility allows them to be easily bent and installed, reducing the need for additional fittings and connections.

Yes, HDPE PE100 polyethylene pipe is safe for transporting drinking water. They comply with stringent standards and regulations for drinking water applications. HDPE is a non-toxic material that does not impart harmful taste, odor, or substances to the water, ensuring its suitability for drinking water systems.

HDPE PE100 Polyethylene Pipe is available in a wide range of sizes, typically starting from small diameters of 16mm and going up to large diameters of 1000mm or more. Pressure ratings, including PN20, PN16, PN12.5, PN10, PN8, PN6, and others, can vary depending on application requirements.

Yes, HDPE PE100 polyethylene pipe is highly weldable. Thermal fusion methods such as butt fusion and electrofusion are commonly used to join HDPE pipes together. These technologies create strong, leak-free joints, ensuring the integrity of the pipeline system.

HDPE PE100 polyethylene pipe is known for its long service life, with a typical lifespan of up to 50 years. Actual lifespan can vary depending on factors such as installation conditions, operating parameters, and maintenance practices.

Yes, HDPE PE100 polyethylene pipe is recyclable. HDPE is a thermoplastic material that can be melted and reprocessed many times without significant loss in properties. High-density polyethylene recycling contributes to sustainability efforts and waste reduction.

HDPE PE100 polyethylene pipe offers many environmental benefits, including:

- Reduce carbon footprint compared to alternative materials.

- Recycling, promoting a circular economy and reducing plastic waste.

- Energy efficiency during production and installation.

- Resist chemical decomposition and reduce the need for maintenance and replacement.

- Lower transportation costs due to the lightweight construction.

Yes, HDPE PE100 pipe shows excellent resistance to a wide range of chemicals, making it suitable for various industrial applications.

Polyethylene is commonly used in water supply systems, irrigation, gas distribution, mining, drainage, industrial processes, and communications.

Yes, polyethylene pipes are safe for transporting drinking water. It is non-toxic and complies with stringent regulations for drinking water applications.

What is the temperature range of polyethylene pipes?

Polyethylene pipe can withstand a wide range of temperatures, typically from -40°C to +60°C (-40°F to +140°F), depending on the grade selected.

Yes, polyethylene pipes are known for their excellent flexibility and resistance to seismic activity, which makes them suitable for installations in seismic areas.

Yes, polyethylene pipes are UV resistant and can withstand prolonged exposure to sunlight without significant deterioration.