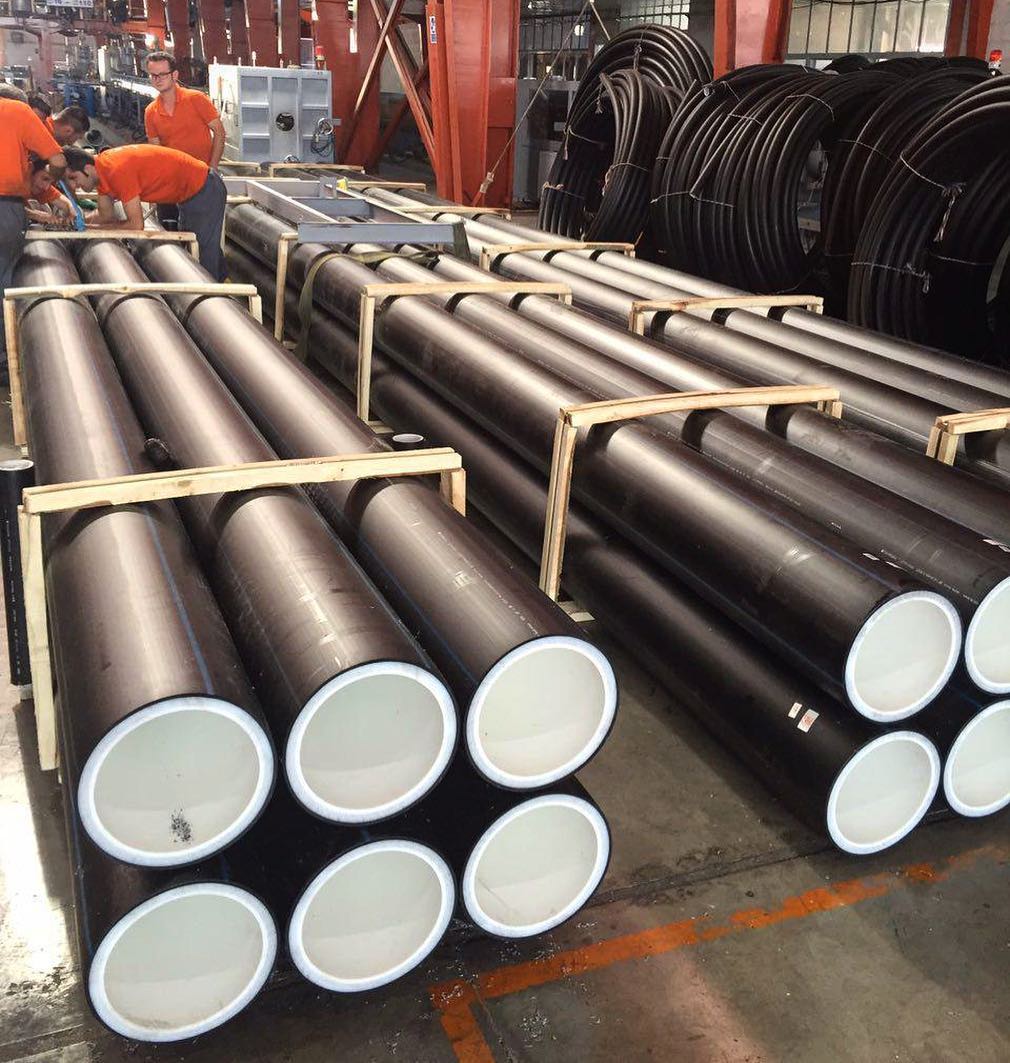

PE tube

Polyethylene pipe is a new type of plastic pipe made of EX3 grades HDPE polyethylene raw materials. Polyethylene is a very simple polymer that is widely used in the manufacture of plastics. The most important application of polyethylene is in the construction of pipes and fittings for water supply, gas supply, and sewage systems in urban and industrial areas.

Elitepipe is a single wall and double wall polyethylene pipe producer with a variety of production in reinforced corrugated pipe and drainage pipe, and is willing to cooperate with all applicants of its products. The pipes produced in Elitepipe complex have got all the required national and international standards in the field of standards and by passing all the standard tests in Elitepipe laboratory complex, they have provided a reliable product in the pipe making industry.

Polyethylene or PE

Polyethylene, abbreviated as PE, is one of the materials produced from ethylene gas, which is synthesized by a process called polymerization. Polyethylene production in the world has brought about a huge change that can be said to change most industries with it.

Primary polyethylene is available in commercial grades PE63, PE80, and PE100. Each of these raw materials is used in the production of polyethylene pipes. Pipes made from each of these materials have their own weight and size and each has its own characteristics.

Polyethylene pipes for water supply - gas - sewage

Polyethylene pipes are distinguished that are manufactured by a company elitepipe Polyethylene pipes and fittings have many advantages, including high quality, reliability of polyethylene pipes and fittings, ease of loading and transportation of polyethylene pipes and fittings due to their relatively low weight, quick and easy installation, and variety, which made polyethylene the best choice in various projects. Also, polyethylene pipe has a suitable bending radius and has very good resistance to impact and pressure at very low temperatures. Acid and alkaline environments, as well as many solutions and chemicals, do not affect polyethylene. This is one of the most important advantages of polyethylene pipes and polyethylene fittings.

What is polyethylene?

Polyethylene is a type of gas that is broken down into polyethylene using some kind of catalyst during the catalyst reaction.

Polyethylene is known by the abbreviation (C2H2).

The density of polyethylene should be between 910% and 925%.

types of polyethylene

The general types of polyethylene include hundreds of different types.

Polyethylene has different grades, for example: X3 – X5 – B13 – 0035 – 0075

Each of these grades is used in plastic industries and its uses are different, for example: X3 is used in pipelines and B13 is used in wind industries. Materials HDPE and LDPE are other types of polyethylene that have both hard and soft structures.

Application of polyethylene pipes in the manufacture of pipes and fittings

Polyethylene pipes have important applications in the piping and fittings industry and are used in the water, gas, wastewater, oil and gas, and fluid transportation industries.

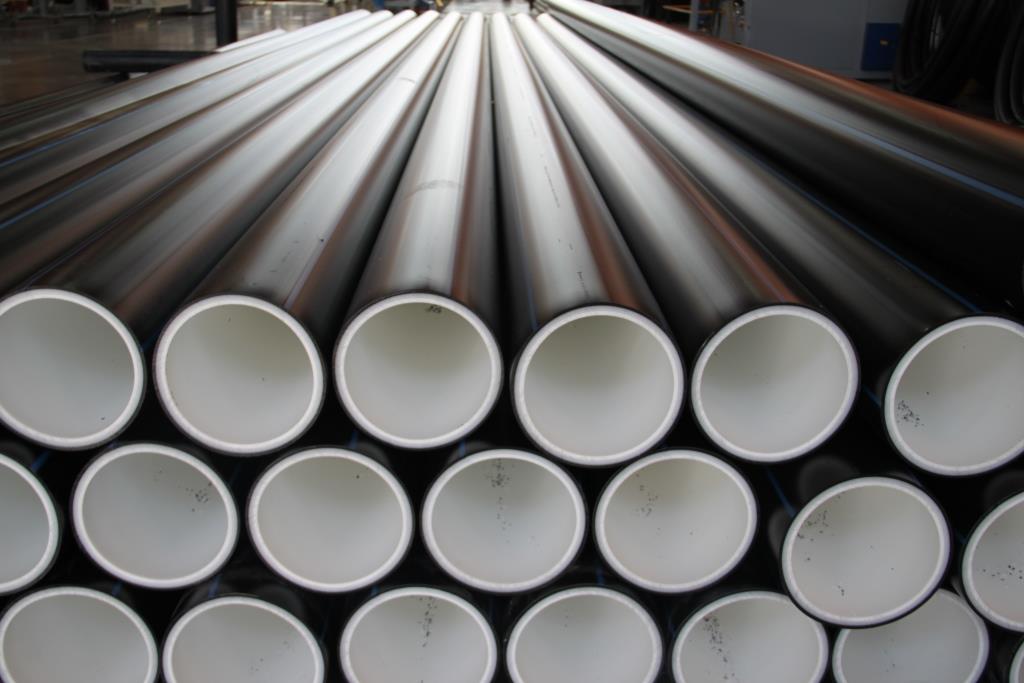

Polyethylene pipes in various shapes and sizes are produced and supplied. single-walled tubes – Carogate tubes – spiral tubes and three-layer tubes; PE80 and PE100 grades polyethylene pipes have the ability to produce, and the production companies set the type of material in the bed and in the production cycle according to customer demand. Polyethylene pipes due to their tensile strength. Ring resistance and high pressure against moisture – rust – decay is the best and most suitable choice for transmission lines.

What is the difference between light and heavy polyethylene?

Heavy Duty Polyethylene Pipe, abbreviated as HDPE, has high toughness and flexibility and is typically used for high pressures and pressurized systems. Lightweight polyethylene pipe, abbreviated as LDPE, is a soft pipe that has high flexibility and is easy to produce. These kinds of materials are easy to form and easy to produce.

Application of different grades of polyethylene

Polyethylene is produced in various grades in petrochemicals and is available to consumers. Heavy HDPE polyethylene grades PE100, PE80, PE63 are available. According to the availability and design in the project, the grade type is requested to the manufacturer, and according to the grade type, the materials are produced according to the required thickness and standards;

PE63 material grade will contain open particles and will have high weight and as a result, the final price will be higher compared to PE100 material. In material grade PE100, because of the continuity and compactness of the material, the thickness of the material will be less and it will bear higher pressure, and the final price is PE100 grade material will be affordable and cheap.In most projects, supervisors and consultants recommend PE100 grade for projects.

polyethylene manufacturers

There are many production companies in the production of polyethylene pipes and these companies produce them with Chinese and European machines. The Association of Polyethylene Pipes and Fittings has designated production companies in grade A and B, and it is determined based on the quality and type of machinery in this level. Grade A in the production of polyethylene pipes has Level 1 standards and European machinery is active in the production lines; Polyethylene pipe and fittings production companies usually offer their products in different capacities, and each production line has the ability to produce in specific volumes and sizes.

questions and answers

Frequently Asked Questions

Polyethylene (PE) HDPE PE100 is a high density polyethylene material classified as PE100, indicating its high performance properties and adherence to set quality standards. It is widely used in various applications due to its excellent properties.

HDPE PE100 polyethylene pipe offers many advantages, including:

- Exceptional durability and resistance to abrasion, chemicals and UV rays.

- High flexibility, allowing easy installation and adaptability to terrain changes.

- Lightweight structure, which makes it easy to handle and transport.

- Long service life, with a typical lifespan of up to 50 years.

- Good flow characteristics, ensuring efficient fluid transfer.

- Recyclability, making it an environmentally friendly choice.

HDPE PE100 polyethylene pipes find wide-ranging applications in various industries, including:

- Water supply and distribution networks for drinking and non-potable water.

- Irrigation systems for agricultural fields, gardens and landscaping.

- Gas distribution pipelines for residential, commercial and industrial uses.

- Mining operations to transport mud and tailings.

- Drainage systems to manage rainwater and wastewater.

- Industrial processes that require transportation of fluids and chemicals.

Yes, HDPE PE100 Polyethylene Pipe is well suited for underground installation. They have excellent resistance to soil movements, external pressures, and chemicals normally found in soil. Their flexibility allows them to be easily bent and installed, reducing the need for additional fittings and connections.

Yes, HDPE PE100 polyethylene pipe is safe for transporting drinking water. They comply with stringent standards and regulations for drinking water applications. HDPE is a non-toxic material that does not impart harmful taste, odor, or substances to the water, ensuring its suitability for drinking water systems.

HDPE PE100 Polyethylene Pipe is available in a wide range of sizes, typically starting from small diameters of 16mm and going up to large diameters of 1000mm or more. Pressure ratings, including PN20, PN16, PN12.5, PN10, PN8, PN6, and others, can vary depending on application requirements.

Yes, HDPE PE100 polyethylene pipe is highly weldable. Thermal fusion methods such as butt fusion and electrofusion are commonly used to join HDPE pipes together. These technologies create strong, leak-free joints, ensuring the integrity of the pipeline system.

HDPE PE100 polyethylene pipe is known for its long service life, with a typical lifespan of up to 50 years. Actual lifespan can vary depending on factors such as installation conditions, operating parameters, and maintenance practices.

Yes, HDPE PE100 polyethylene pipe is recyclable. HDPE is a thermoplastic material that can be melted and reprocessed many times without significant loss in properties. High-density polyethylene recycling contributes to sustainability efforts and waste reduction.

HDPE PE100 polyethylene pipe offers many environmental benefits, including:

- Reduce carbon footprint compared to alternative materials.

- Recycling, promoting a circular economy and reducing plastic waste.

- Energy efficiency during production and installation.

- Resist chemical decomposition and reduce the need for maintenance and replacement.

- Lower transportation costs due to the lightweight construction.

Yes, HDPE PE100 pipe shows excellent resistance to a wide range of chemicals, making it suitable for various industrial applications.

Polyethylene is commonly used in water supply systems, irrigation, gas distribution, mining, drainage, industrial processes, and communications.

Yes, polyethylene pipes are safe for transporting drinking water. It is non-toxic and complies with stringent regulations for drinking water applications.

What is the temperature range of polyethylene pipes?

Polyethylene pipe can withstand a wide range of temperatures, typically from -40°C to +60°C (-40°F to +140°F), depending on the grade selected.

Yes, polyethylene pipes are known for their excellent flexibility and resistance to seismic activity, which makes them suitable for installations in seismic areas.

Yes, polyethylene pipes are UV resistant and can withstand prolonged exposure to sunlight without significant deterioration.